From Prototype to Mass Production - Using CNC laser cutting to scale your operation

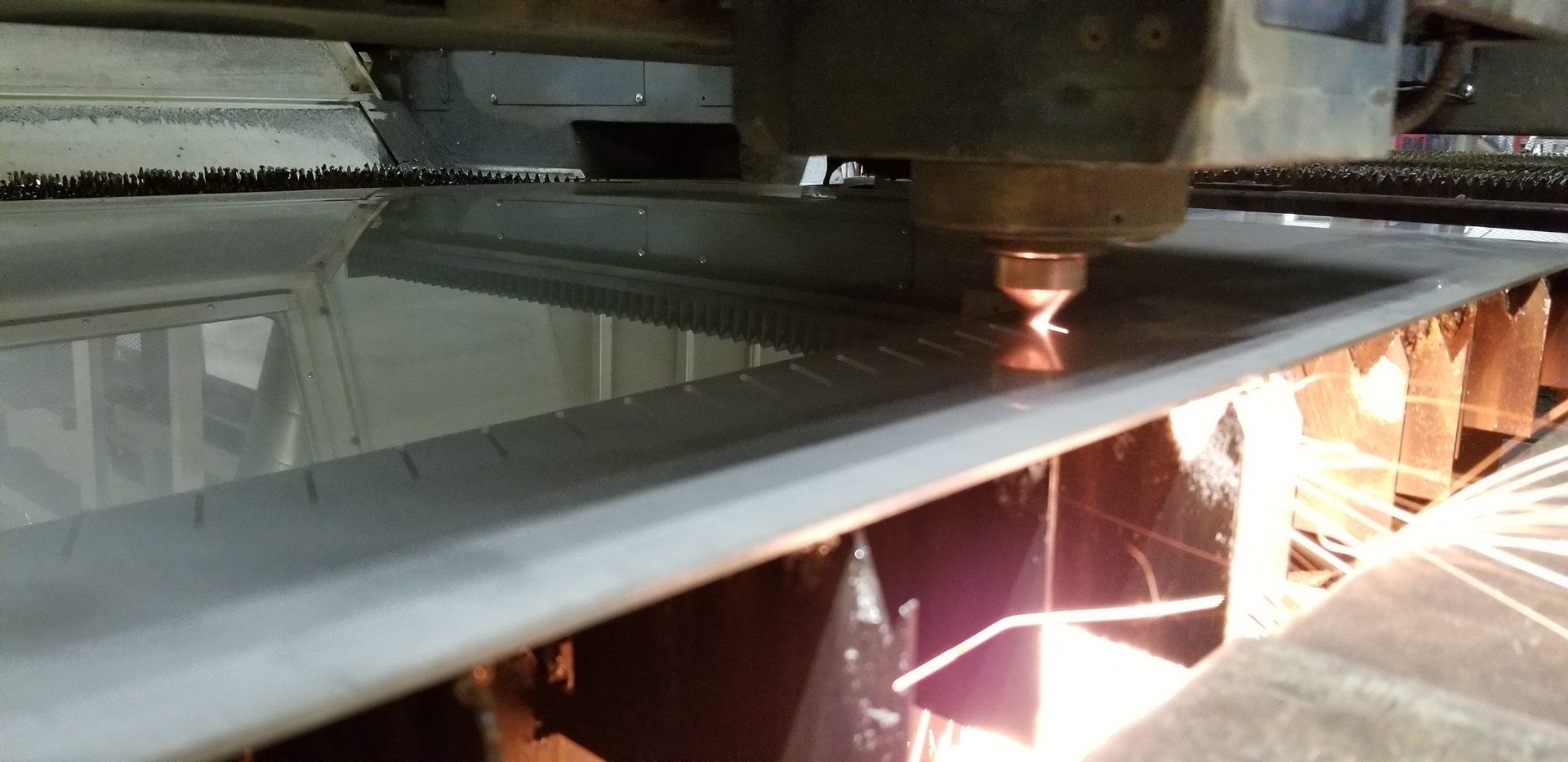

CNC laser cutting, using Computer Numerical Control to guide a powerful laser beam, frees your products from the limitations of in-house fabrication and traditional construction. You can easily create pieces that reflect your designers’ vision and try them out. Quick and cost-effective production of prototype materials means that you can respond in real time to marketing tests, design changes, and material choices. For production the CNC laser turns into a copy machine, automatically producing the quantities you need.

CNC laser prototyping and production follow the same basic steps:

- Design

- Material choice

- Data file review

- CNC laser processing

- Product assembly

Creative and Versatile

The versatility and precision of CNC laser cutting make it a go-to technology for initial product development and ongoing production. Your design files are quickly turned into the pieces you need, from intricate artistic work to signage and product enclosures. Your designers are freed from the limits of traditional sheet metal or plastic construction and can create functional designs to spec using cardboard, plastic, wood, metal, and other materials.

Beyond Machining Capability

The laser cuts cleanly for a finished look, following curves, creating cutouts, and etching patterns and lettering beyond the capability of traditional machining. Everything is completed without transporting the material from one machining station to another, yielding speed, precision, and great results.

Simple Design, Simple Production

Your new product design has never been easier -- we use software to create and model the pieces, then deliver the resulting data file for review before production. The complex and costly tooling you may be used to is cut down to data file preparation. Send a file for each piece that you need or work with us to design, and go ahead with single-unit production rather than waiting for the model shop to produce that initial prototype.

With CNC laser production, you can check form and fit with the real thing, then go ahead with quantity production or make units on-demand as orders come in. Whether you’re a startup watching your budget or a large company that values just-in-time stocking, you don’t have to juggle add-on costs which vary by your strategy.

Advantages of Laser Cutting

Laser cutting is quick, clean, and does the work of an extremely thin tool. The kerf, the material that the tool removes because of its size, is small and the tool turns on a dime, so these systems are being used by artists to produce ornate pieces that once only a lifetime of craftsmanship could create. The laser can cut through paper, wood, plastic, and even metal allowing you to use the same process to create paper cutouts, plastic models, and metal production units.

Don’t Be Blocked by Startup Costs and Tooling

CNC laser cutting keeps the “bumps” of design and production minimal so your project has fewer big decisions to make and more green lights. Your turnaround for custom projects will impress your customers as you respond to design changes and new ideas without long lead times and expensive retooling.

Moving smoothly from prototype to production volumes means not only an easier product launch, but the reassurance that what comes out of your production facility is exactly what you created in the prototype phase. Turn to CNC laser production to get started on your project, and you will see the product you envisioned, faster and easier than you imagined.