The role of ERP in Laser Cutting

- By Justin Hannah

- •

- 21 Feb, 2018

- •

Laser cutting technology has been widely implemented in many industries particularly the manufacturing industry. This technology is used in cutting most types of materials including metal, rubber, polymers, plastic, stone and glass among others. It comes with a lot of benefits such as reducing production cost and time, optimal utilization of materials and producing high quality designs.

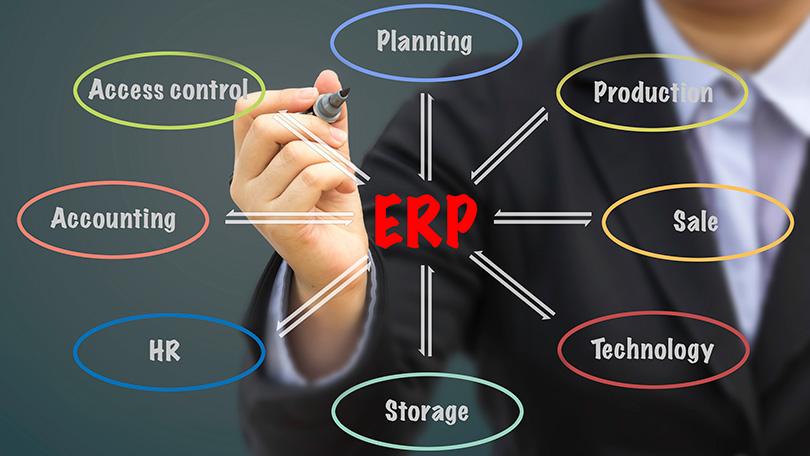

However, Laser cutting systems are not fully efficient on their own and need to be integrated with Enterprise resource Planning (ERP) Systems so as to streamline the operations and to equip you with real time information at every stage. The ERP plays the following roles in the laser cutting industry

- Making estimates and quotations

Making estimations and quotes is a very important process in a business as it may make or break a deal with a prospective customer. Lesser time-to-quote translates to a good reputation and business opportunities amid stiff completion in the industry. The cost estimates should be arrived at in the shortest time. An ERP helps giving real-time information on the Bill of Materials to be used at every stage and the cost, enabling you to make cost estimates and issue quotations in the shortest time possible.

- Inventory management

Laser cutting operations are very dynamic and in most cases very unpredictable as they depend on what different customers want. An ERP is responsible for keeping track of materials (inventory) right from when they are purchased to when they are consumed. You are able to get timely alert as to when a particular inventory has reached a set amount and needs replenishing. The ERP helps you maintain a good amount of inventory, reduce costs for storage and restock in good time.

- Nesting and Integration with other Systems

Different customers’ orders vary in designs, dimensions and quantities. When the orders are simultaneous, absolute control of inventory is necessary to ensure there is minimum or no wastage. An ERP will help the cutting operation in optimizing inventory usage by integrating nesting applications to manage usage of inventory and reduce costs. The nesting module is able to track the remaining inventory after previous operations and the ERP is able to track the inventory and facilitate reordering when necessary. This will help your business in optimal material utilization and eventual reduction of the cost of inventory.

- Maintaining High Quality

Laser cutting needs to have mechanisms that ensure that high quality products are produced. Since most of these products are used in industries that are highly regulated, it is critical that the quality is controlled at every stage of the process. An ERP will ensure that these quality standards are enforced as it is integrated with a core manufacturing execution systems (MES). The ERP ensures there is continuous measurement of quality parameters at all stages so that corrective measures can be immediately effected when defects are detected.

- Interfacing with other Applications

To fulfil end-to-end operations, the ERP will need to interface with other applications. The ERP has to be integrated with other applications used in laser cutting operations that complement each other. You will be able to trace the products more easily when the ERP is integrated.

These are among the roles played the ERP solutions in the Laser cutting operations. Our company offers High quality CNC laser cutting services in Michigan. We use applications are integrated with ERP systems that ensure that we give you timely and accurate quotations, your orders are processed within the shortest time possible and our products meet the required industry standards and the requirement of our customer.

CNC laser cutting, using Computer Numerical Control to guide a powerful laser beam, frees your products from the limitations of in-house fabrication and traditional construction. You can easily create pieces that reflect your designers’ vision and try them out. Quick and cost-effective production of prototype materials means that you can respond in real time to marketing tests, design changes, and material choices. For production the CNC laser turns into a copy machine, automatically producing the quantities you need.

CNC laser prototyping and production follow the same basic steps:

- Design

- Material choice

- Data file review

- CNC laser processing

- Product assembly

Creative and Versatile

The versatility and precision of CNC laser cutting make it a go-to technology for initial product development and ongoing production. Your design files are quickly turned into the pieces you need, from intricate artistic work to signage and product enclosures. Your designers are freed from the limits of traditional sheet metal or plastic construction and can create functional designs to spec using cardboard, plastic, wood, metal, and other materials.

Beyond Machining Capability

The laser cuts cleanly for a finished look, following curves, creating cutouts, and etching patterns and lettering beyond the capability of traditional machining. Everything is completed without transporting the material from one machining station to another, yielding speed, precision, and great results.

Simple Design, Simple Production

Your new product design has never been easier -- we use software to create and model the pieces, then deliver the resulting data file for review before production. The complex and costly tooling you may be used to is cut down to data file preparation. Send a file for each piece that you need or work with us to design, and go ahead with single-unit production rather than waiting for the model shop to produce that initial prototype.

With CNC laser production, you can check form and fit with the real thing, then go ahead with quantity production or make units on-demand as orders come in. Whether you’re a startup watching your budget or a large company that values just-in-time stocking, you don’t have to juggle add-on costs which vary by your strategy.

Advantages of Laser Cutting

Laser cutting is quick, clean, and does the work of an extremely thin tool. The kerf, the material that the tool removes because of its size, is small and the tool turns on a dime, so these systems are being used by artists to produce ornate pieces that once only a lifetime of craftsmanship could create. The laser can cut through paper, wood, plastic, and even metal allowing you to use the same process to create paper cutouts, plastic models, and metal production units.

Don’t Be Blocked by Startup Costs and Tooling

CNC laser cutting keeps the “bumps” of design and production minimal so your project has fewer big decisions to make and more green lights. Your turnaround for custom projects will impress your customers as you respond to design changes and new ideas without long lead times and expensive retooling.

Moving smoothly from prototype to production volumes means not only an easier product launch, but the reassurance that what comes out of your production facility is exactly what you created in the prototype phase. Turn to CNC laser production to get started on your project, and you will see the product you envisioned, faster and easier than you imagined.